Feeding Systems for Fish Farms and RAS

| Mon, 02 Nov 2020 - 11:54

Let's do a little history. The concept of automatic feeding was born and developed in Norway in the early 1980s. The first equipment was developed for sea cage feeding and was very basic. This equipment consisted of a hopper with a capacity of less than 200kg of processing power, a blower to send the feed to the cages and an auger screw to drive the feed from the silo.

Over the years, the evolution of technology and the demand for equipment with greater performance led to new solutions appearing on the market such as revolver type feed distributors and software that allowed for greater control over feeding.

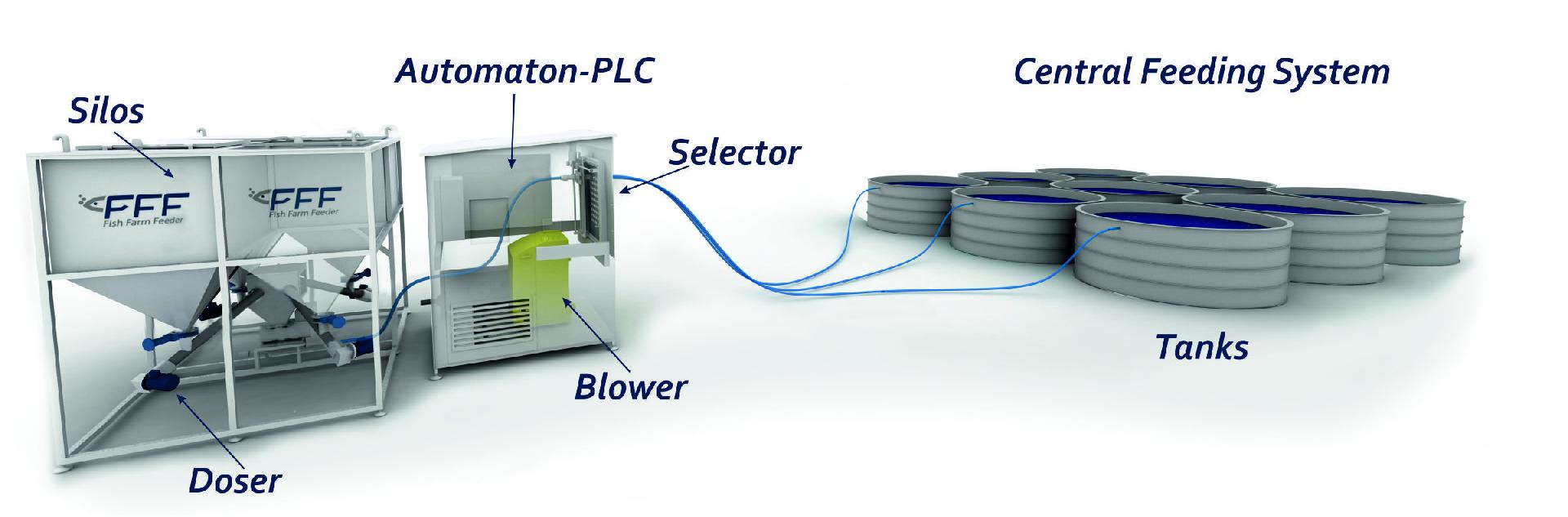

These centralised systems consist of a central station where the silos and all the (automatic) dosing, distribution and control elements are located. The distribution of the feed to the different tanks is done by means of a fluid (typically air in the pneumatic systems) that flows through pipes.

Early in this decade, with the evolution of robotics and artificial intelligence, new power feeding systems have been fully designed and optimised for land-based and RAS systems to emerge from.

Silos

Silos, as necessary tools for safe feed storage, vary in number and capacity according to the needs of the aquaculture company using them. They can be manufactured in various types of material (stainless/galvanised steel, fiberglass, polyethylene, etc) and must be certified for food purposes. They can also be standard or custom-made to cater to the clients needs. An angle at the bottom of the silo ensuring that the feed falls easily is recommended.

Also read: Automatic Submersible Fish Cage Systems Counter Weather, Surface Problems

Doser

Two dosing systems are usually used for feed dosage: Gravimetric and volumetric.

1. Gravimetric systems are based on weighing the doses by means of one or more electronic load cells. The only unit of measurement is weight

2. In volumetric systems the dosage is made according to the volume. In such systems, it is essential to calibrate the dosing element according to the type and size of feed to be used. It is necessary to establish what quantity of mass the dosing element has to dose in a defined period of time. When feed and batch are changed calibration should be carried out.

Depending on the manufacturer, different types of volumetric dosing units can be found. The most common ones are dosers and auger screws. The auger screw-based system is the most widely adopted to achieve accurate dosing of feed from the hopper. The very thrust of the auger is what makes the precise amount fall into an intermediate hopper, and it is in such a compartment where the various mixtures from several hoppers (up to four) converge to achieve the feed mixture defined by the fish farmer.

This functionality allows different sizes of pellets and/or types of feed to be included in one dosage at the same time in a certain proportion. A rotary valve or shutoff located downstream of the intermediate hopper allows the already dosed feed to be regularly introduced into the feed line, avoiding clogging.

Also read: OptiFarm - Optimal Water Quality and Healthy Fish On Land

Selector

The selector is the device that aims to distribute the feed to the different tanks by selecting an outlet, which is linked to the tank by means of an HDPE pipe.

Here we find two types of selectors:

1. The 'revolver', a system wherein the outlets are placed in a circle and the selection of the mouth is done by a motor with a reducer

2. The 'matrix', where the outputs are placed in a matrixial way and the selection of the port is done by two servomotors, one on the X axis and the other on the Y axis.

Advantages of matrix vs revolver

These are the main advantages of matrix selectors:

- More tanks: Taking a pipe diameter of 32mm as a reference, if we have 60 outlets on a revolver in a matrix system, we will have 180 outlets. Less space also means to solution is more robust

- Increased speed: The movement in the revolver mechanisms is rotary while in the matrix system it can follow the X or Y axis, obtaining a speed of displacement between outputs up to three times faster

- Low maintenance: Less maintenance is required due to the unique design.

Feed transfer pipe

The pipe used to deliver the feed from the selector to the distributor is usually made of HDPE to increase its durability against abrasion wear. The pipe must have a high enough section to minimise the pressure loss and to prevent the feed from traveling at such high speeds that could it could deteriorate in quality. Another important point is to avoid sharp bends in its installation; the piping should be as straight as possible.

Control systems: PLC

To control all the elements of the feeding system, PLCs are used together with frequency variators that allow modifying the rotation speeds of dosers and blowers according to the quantity requested and the distance that the feed has to travel to the feeding point. The handling of these parameters programmed from the software means that the distribution of the feed is optimised in terms of quantity and time without damaging the pellet.

The new feeding systems also allow to integrate oxygen sensors that automatically adapt feeding according to the oxygen level in the tank, temperature sensors, pH and any other parameters that need to be monitored.

Also read: CPF Builds “Aquaculture 5.0” Shrimp Farm In The USA

Blower

Blowers are the devices that generate the fluid (air) used to transfer the feed from the dosing components to the tanks. Transportation must be done as smoothly as possible to avoid damage to the feed, but at the same time to avoid clogging the pipes that carry the feed.

In order to control the flow of air into the pipe and, thus, control the speed at which the feed flows through the pipe, frequency variators are used. With these variators, the speed of rotation is regulated. An air cooler and/or dryer is usually installed at the blower outlet to prevent damage to the feed due to the temperature the air reaches when compressed.

Disperser: Spreader

The spreader is used to disperse the food in the tank. This is located at the end of the pipe that brings the food. Its main function, besides throwing the pellet, is to distribute it in a homogeneous way.

Software

As important as having a feeding system is, having a program that allows us to manage all the feeding parameters, so that we can manage feeding plans tailored to the fish farmer and integrate it with the farm management software is also vital. Integration with mobile devices such as smartphones or tablets is another requirement that any feeding system should offer.

Why choose an automatic feeding system?

The implementation of this type of system provides a number of benefits:

- Improved feed conversion ratio

- Decrease in size dispersion

- Increased growth rates

- Reduction of feed waste

- Significant savings in manpower

- Low maintenance costs

- Programming and total control

- Monitoring by computer, smartphone or tablet

- Software can be integrated with the farm management program

- Integration of sensors (dissolved oxygen, temperature, pH, etc.)

- Feed and batch traceability

Source: Aquafeed.co.uk